CNC Milling

CNC Milling

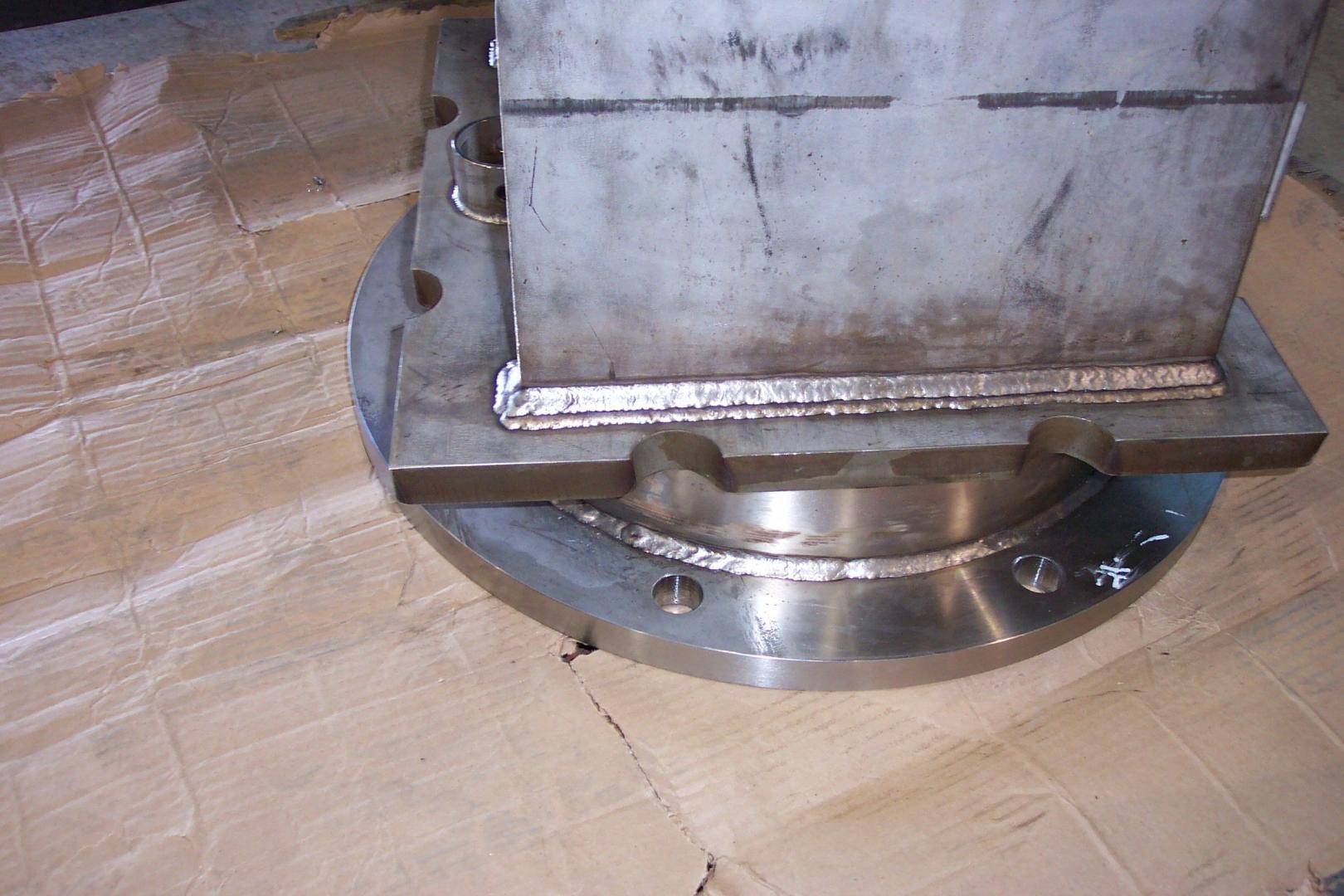

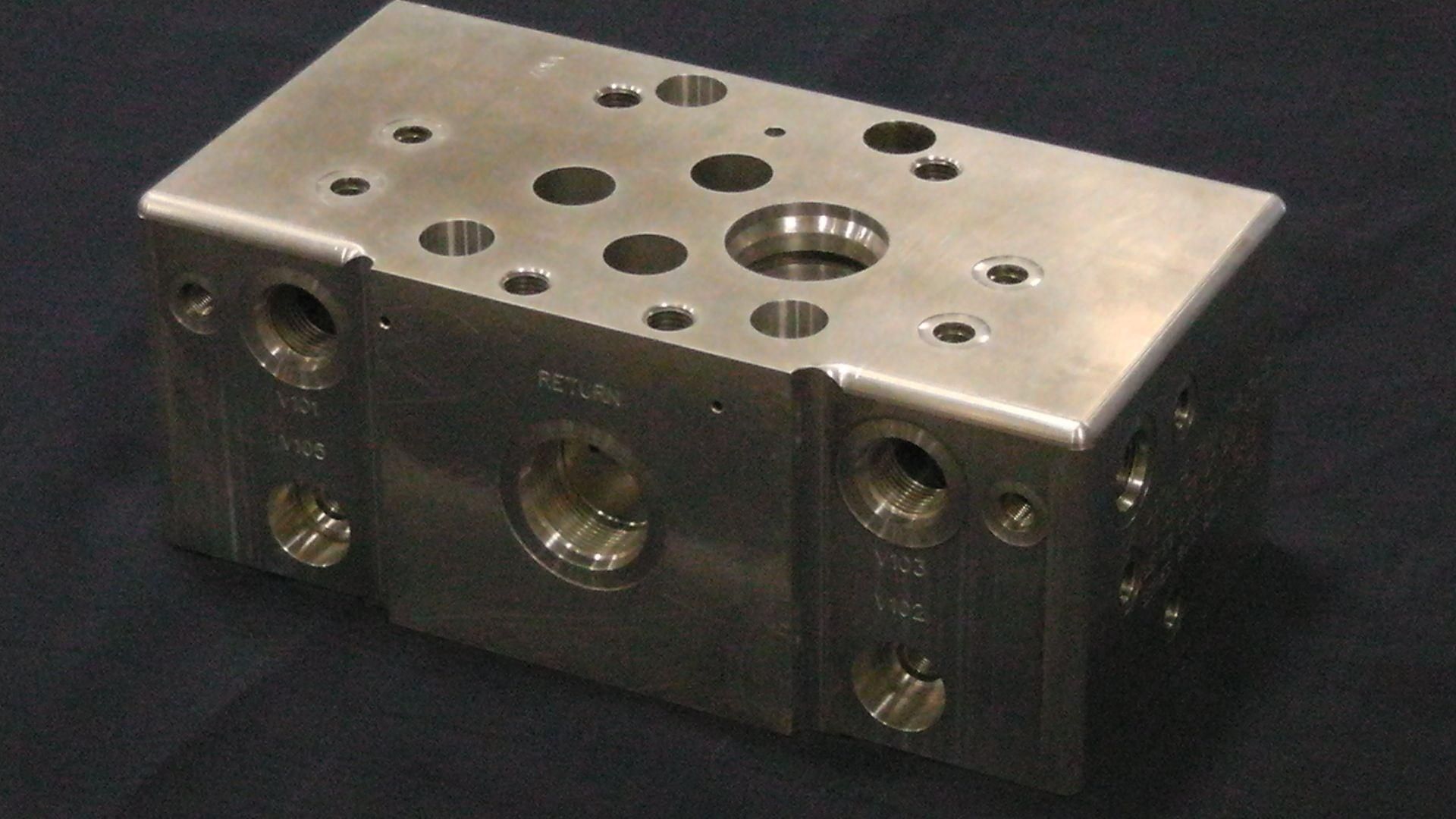

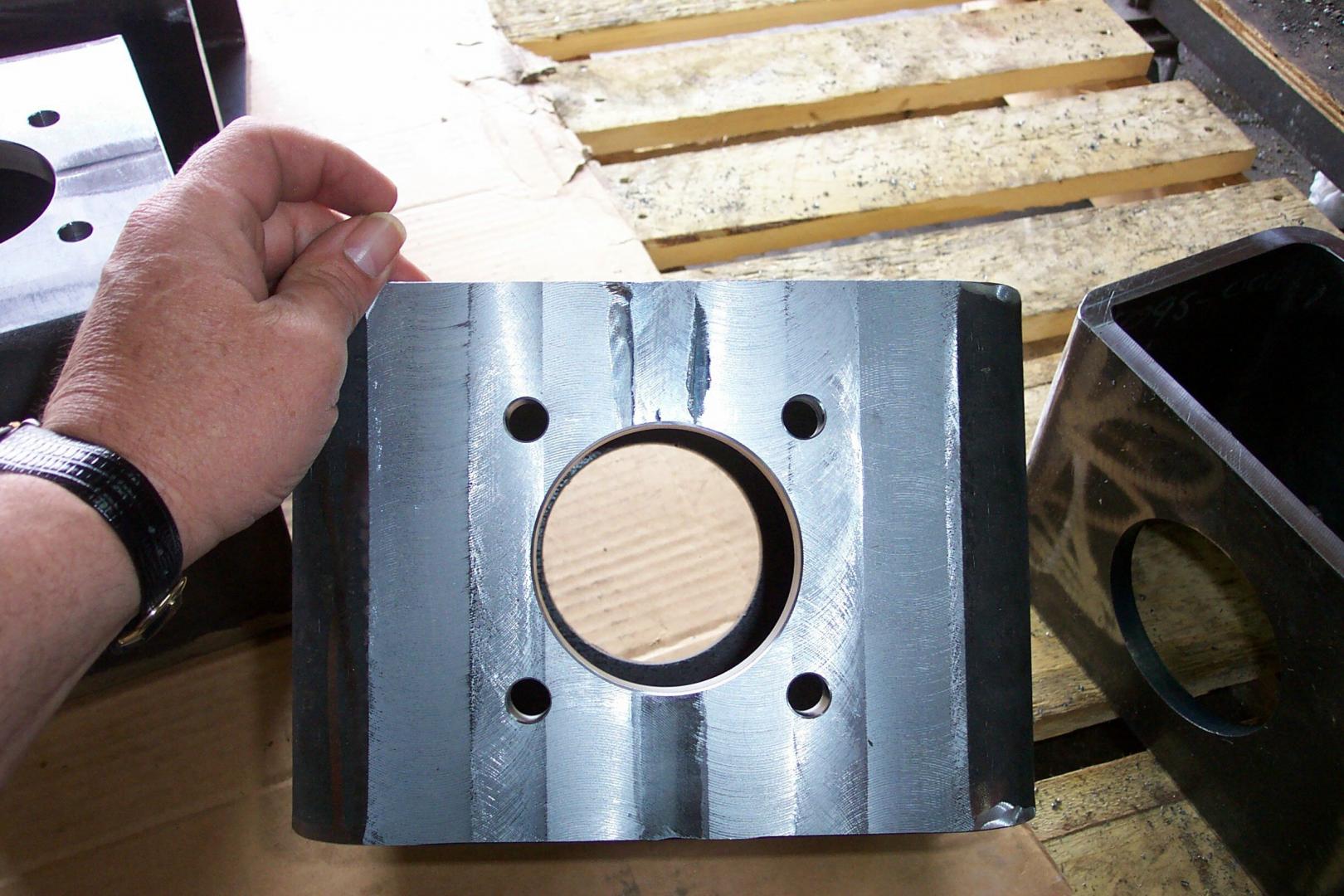

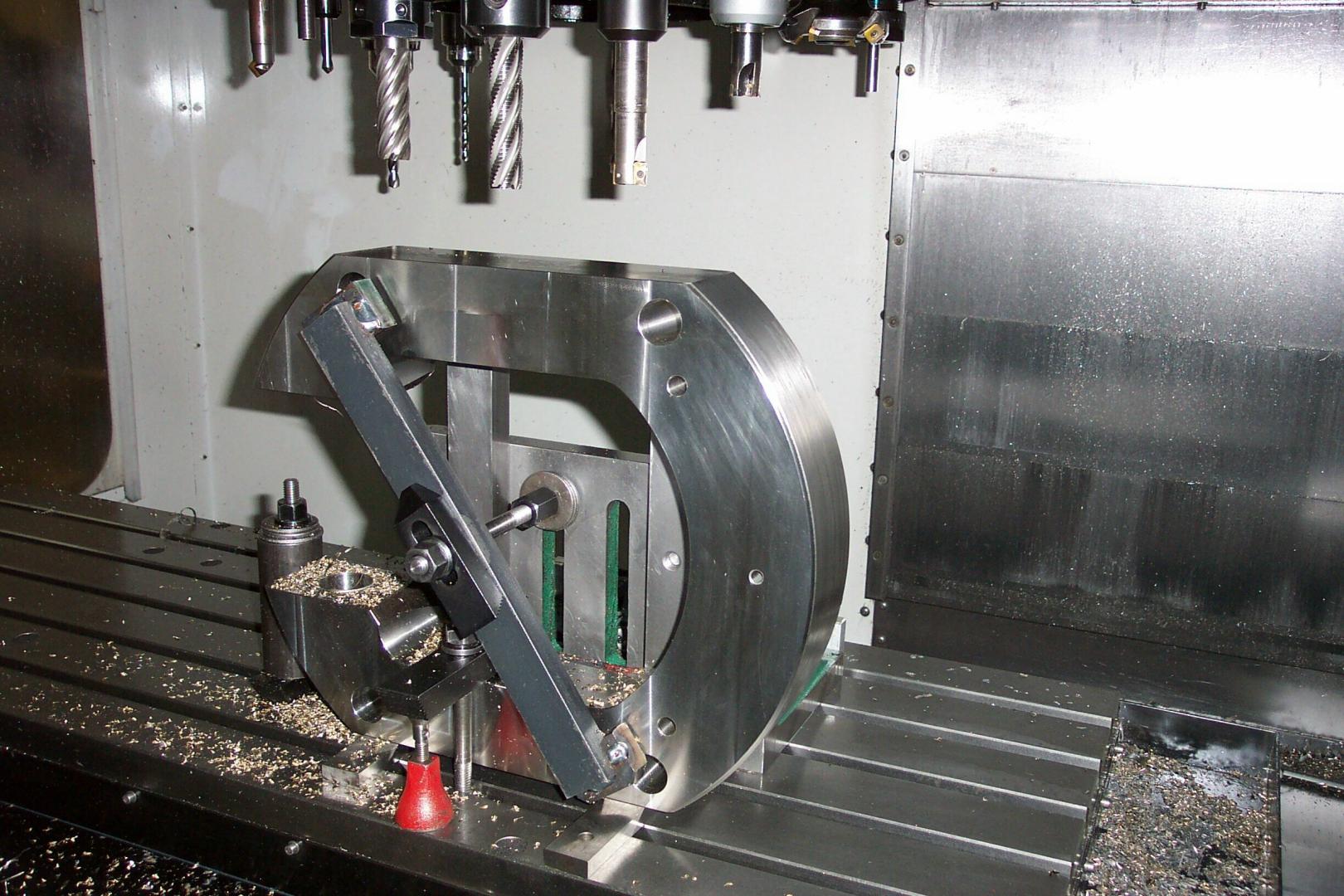

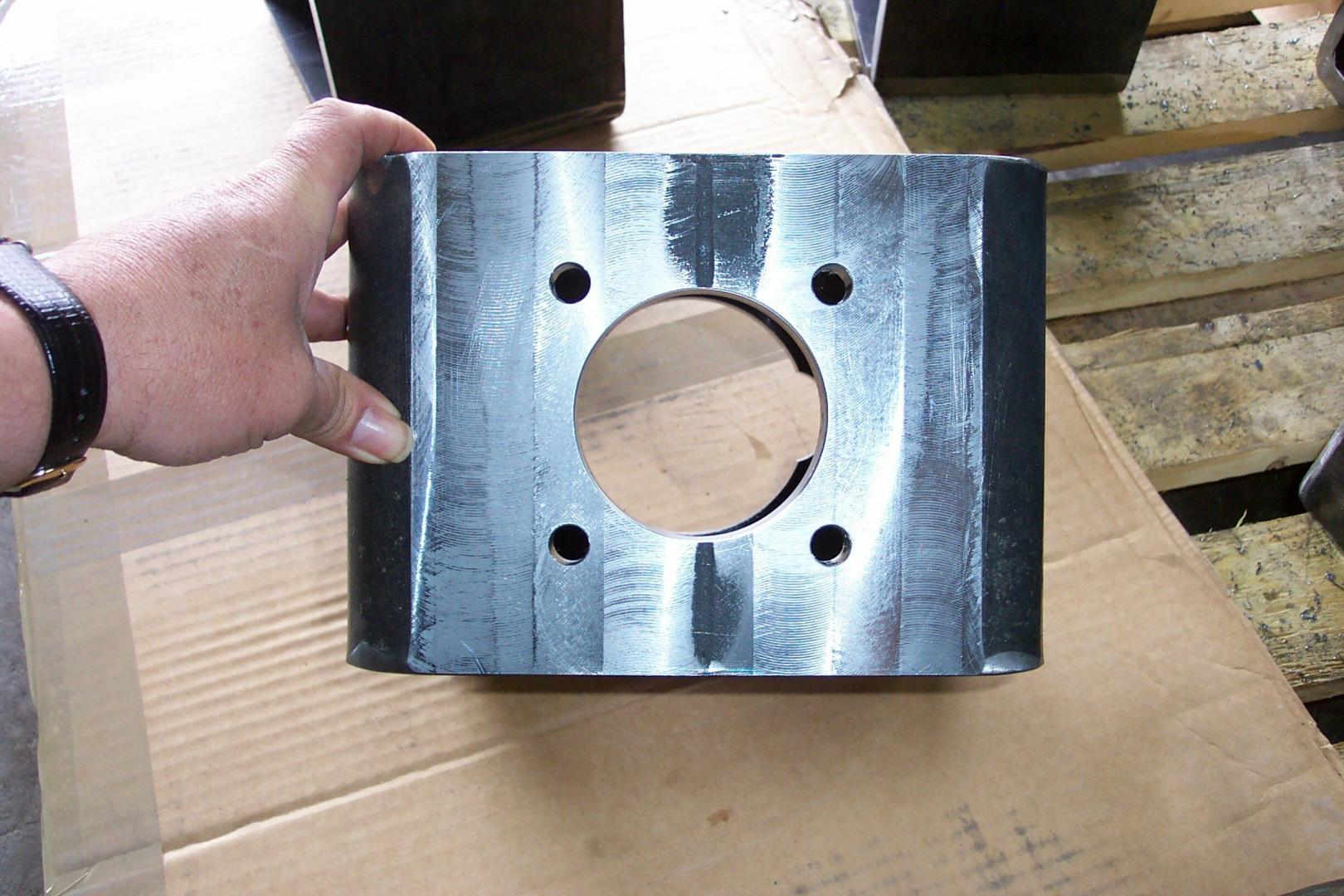

Mainly defined by a rotating tool used to roughen a raw part until the desired profile is obtained according to the requirements. Usinage CNC Production uses full 4-axis numerical processes to achieve any form of part configuration on all types of steel alloys as well as stainless-steel grades, cast iron alloys and aluminum even up to different plastic alloys.

A MACHINING PROCESS THAT TAKES PLACE IN 4 PHASES

Being specialists in CNC machining, we offer various services

- Production of Parts in Single Units or in Series

- Custom Manufacturing

- Surface Treatment

- Industrial Drawing

- Delivery Service

Our service area

extends throughout Quebec, and mainly in

Joliette

Montreal

South Shore

Are you looking for skilled welders in Joliette or its surroundings? Contact the company Usinage CNC Production.

THE ADVANTAGES OF CNC MILLING

Thanks to the milling technique, we can guarantee a high output and a perfect finish. For more than 20 years, many professionals have used our services for the production of jigs and finished components in small series. In addition to CNC milling, CNC lathing is also an operation that we are very familiar with. Our services are dedicated to professionals in the Lanaudière region, Montreal and surrounding areas.

HIGH EFFICIENCY AND A PERFECT FINISH

MILLING CAPACITY

Usinage CNC Production Inc. is a leader in the field of numerical control machining. At the milling level, the company has four numerical control milling units offering 2D & 3D machining services on small and large-scale parts

1 Milling Park of 5 Units

- Okuma ES-V4020 4 AXIS 20 x 40 Machining Centre

- Second Okuma ES-V4020 3 AXIS 20 X 40 Machining Centre

- VF 4 HASS 22 X 50

- Kiheung U1000LT 38 Pcs X 90 Pcs

- MILLING CENTER KITAMURA MYCENTER4XD

CAPACITY X = 50 Y= 24.2 Z = 24.2